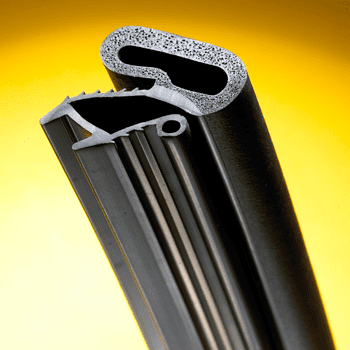

Solid rubber

An extrusion is a seal between two surfaces. Most extrusions are created from solid or sponge rubber. Solid rubber is most commonly used for glazing throughout the automotive industry and for pipes and seals. Solid rubber can be single or co-extruded to combine different colours and materials. This type of rubber will often have excellent heat and fuel-resistant qualities, making it ideal for glazing and seals.

Send Enquiry