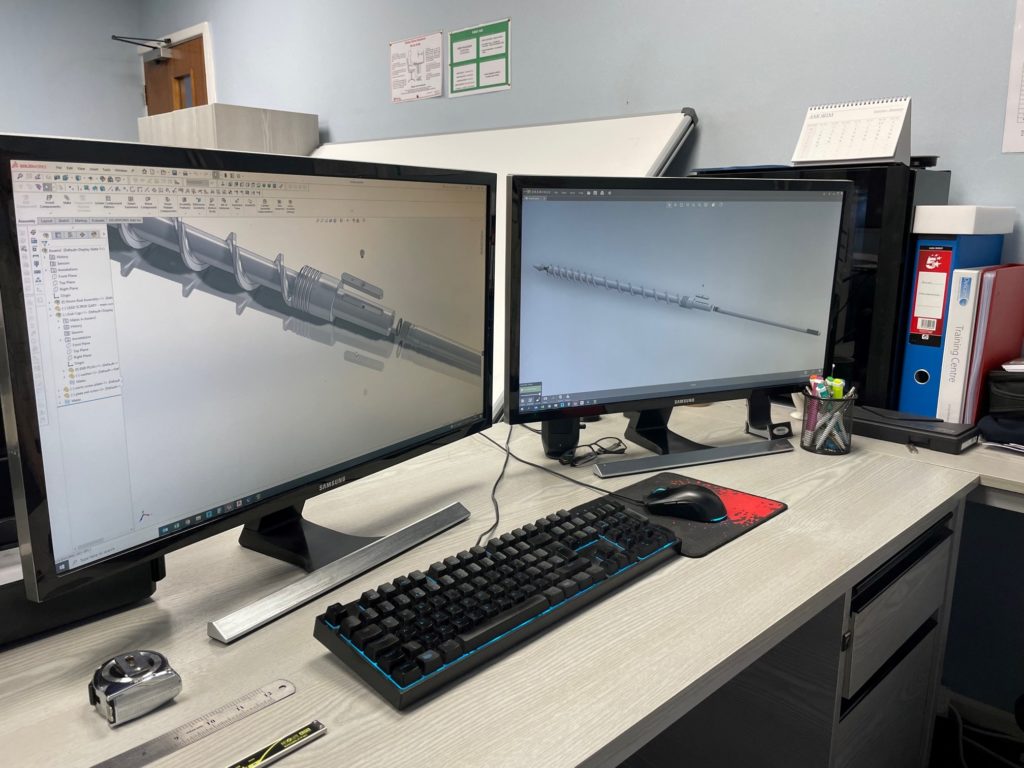

Over the last five years we have invested in our design and development department, using the latest and up to date software working with Solidworks, AutoCAD, Vectric and Igems we are able to work with customer files for 3D solid modelling and 2D projects. We can work from an existing file or from the actual parts using a digitiser or from just an idea. We are able to present our customers with a fast turn round when it comes to putting their ideas into clear and understandable drawings.

Our drawing team supply all of our customer drawings and production drawings that cover all of our manufacturing needs that include, extrusion die drawings, press tool drawings, CNC drawings for our routers, flash cut machines, 3d printers, waterjets and profilers. Working with Igems to create the most efficient nesting programs to maximise material usage.

The CNC departments have a great deal of flexibility, with routing, profiling and cutting with high precision. We also have a 5-axis waterjet with high cutting speeds and multiple heads leading to increased productivity and more control over what and how we design. We offer design solutions giving our customers the support needed to see their projects through.

We are always looking to new technologies and machines in our development program. The latest is 3D printing. Developing our ability to make jigs and prototypes in house. This opens up new and unique possibilities for advanced engineering design and increased productivity.

Our tool room makes all of our dies, fittings and fixtures and many of our jigs. Using AutoCAD, BobCAD and Fusion 360, the CNC milling machine and CNC wire eroder ensure we have the tools to meet the tolerances specified by the design team.